|

The

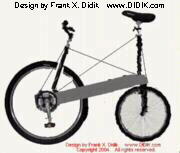

Quest for the worlds lightest bicycle

The

under 4 lbs (1818 gram) bicycle

By Frank X. Didik

September 16, 2006

Purpose: The goal of this design construction project

was to create the lightest practical bicycle. The lighter the

bicycle, the easier, it is to operate and potentially the faster and

farther to travel, in a given time period.

Issues: The major issues in designing a super light

weight bike is the weight of the wheels, tires, drive components

(crank, pulley's, drive belts or chains or drive shaft), and the

wight of the frame. In addition, the craftsmanship and engineering in

key areas are essential to minimize energy loss do to friction and

excess wight. These include the machining of the wheel bearings, the

minimal wight of the frame and the choice of ultra strong but

non-conflicting materials. After studying a number of existing light

weight bicycles, I noticed that some of the bicycles used expensive

lightweight materials, such as carbon fiber, which, under certain

circumstances, can be made very strong, but because of the way that

these bicycles were constructed, the designs did not take advantage

of the unique properties of carbon fiber. Thus in some cases, excess

carbon fiber material was used, and in other cases, not all the

potential stresses were considered and the bicycle had the potential

for catastrophic failure of the carbon fiber. In other cases, I

noticed that the bicycles used mixed metals, such as steel and

aluminum. Such use of mixed metals can create galvanic reaction or

battery effect with the intersection area of the two metals gradually

being compromised do to rapid corrosion. It is interesting to note

that I have also observed the same flaw in a very expensive Italian

automobile design. Had the company taken precautions to shield the

mixed metal body, the sports car would not have been prone to such

rapid rusting. The stress and strain on the crankshaft and the frame,

is enormous and these components must be strong enough to endure high

loads, hour after hour.

Solution: Unfortunately, the solution to the issues

outlined above is not simple. Extremely or ultra light weight

materials capable of enduring the huge physical forces either do not

exist today or can not be readily engineered into a structurally

sound bicycle light enough to achieve and break the 1818 gram / 4lbs

weight goal. One method employed, that was not completely

satisfactory, was to form the frame out of lightweight Styrofoam,

with a thin hollow steel (yes steel) rod in the center. The Styrofoam

itself was covered with a thin layer of carbon fiber material. This

created an incredibly light "frame". The steel rod served

several purposes including to provide a certain degree of stability,

to maintain shape in case the carbon fiber - Styrofoam frame failed

and equally as important, to serve to hold the wheel bearing housing

and to provide and anchorage point for the necessary piano wire

stress and strain cables, which stabilize the frame to the steering

column and seat column. In the photographs above, the bicycle to the

left was lighter than the bicycle to the right, however it was found

to be very unstable and ran a constant risk of falling backwards. To

alleviate this, the bicycle to the right was designed to have a

non-drive small rear free turning wheel. I suppose under strict

definition, this should be referred to as a tricycle variant. The

free turning rear wheel solved the instability and in fact made the

"bicycle" feel substantially stronger. The wheels were

stripped down to a level of just adequate, with the tires glued on to

a "rimless" rim.

Additional Design Information Available A fair amount

of unique information was gathered through careful design, testing

and trial and error and many existing mistakes and flaws were

uncovered during this process. If you are a manufacturer of bicycles,

motorcycles or specialty cars, you may wish to contact this designer.

The author of this article can be

reached by email at "bicycle at didik.com".

To control spam, which recently has reached the level of thousands

per week, please summarize the purpose of the email, in the heading

such as "bicycle design" or "cycle engineering"

or "can you help with our bicycle design". Thank you. |

Other

pages on DIDIK.com covering alternate

energy vehicles:

This "1818" bicycle design was found to be

lighter, but had major instability problems including the potential

to fall backwards. The piano wire served to stiffen the structure.

The above "1818" bicycle could in fact be

considered a hybrid tricycle since it incorporates a small free

turning wheel in the rear. This bicycle arrangement, though heavier

than above, proved to be substantially better in several ways

including stability and strength. |